Letter to the Editor

In response to the last newsletter, FTE Jeremy S. sent photographs of Aussie instrumentation he had worked on over the past decade.

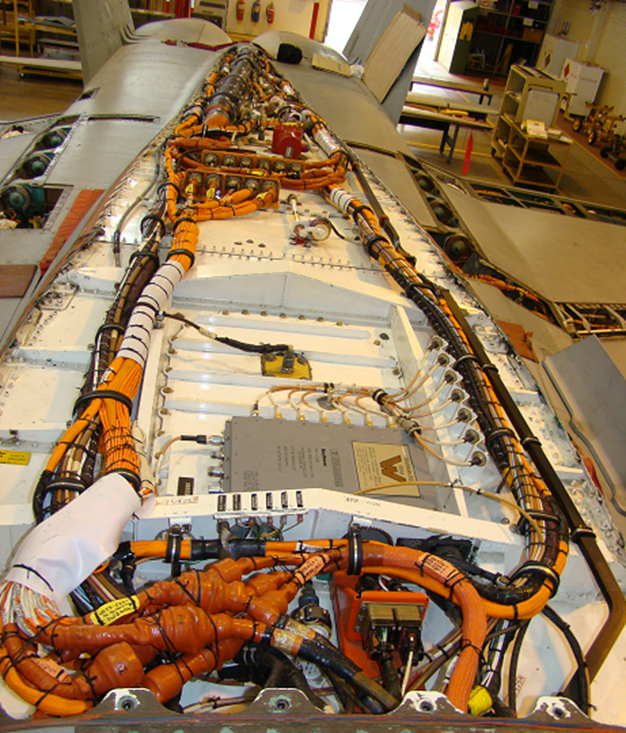

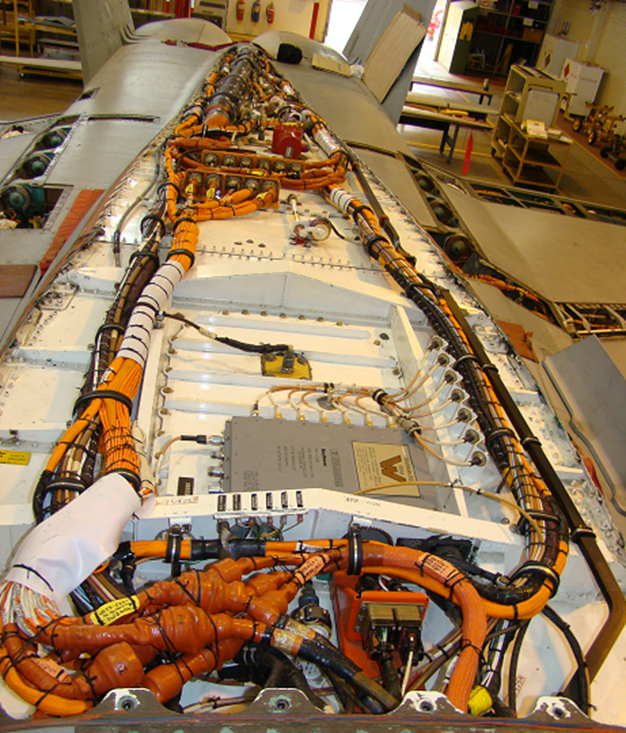

The only real Frankenstein aircraft we had in recent years was our classic Hornet A21-032 which was heavily instrumented with everything you could want – strain gauges, accelerometers, cameras at various stations for stores clearance with a pallet in the gun bay. This picture was taken down the spine as we prepared to de-modify the aircraft and return it to the fleet. As it was our lowest hour hornet, they wanted it back! Though it had the most fatigue hours due all the flutter/loads testing…

PC-9 Loads Monitoring

We were tasked to install a loads monitoring system to the PC-9 due early fatigue cracking in the RAAF fleet. This was a classic wired system. Soon after install, one of the training units bent the rudder with over 70G local acceleration recorded in that control surface. We also had a heavily instrumented PC-9 (A23-045) but I can’t find any pics of when we tore out all the wiring – like a waterfall of wiring from the wing root.

Supersonic Camera Pod

Concept for a more streamlined camera pod to observe supersonic weapons clearances. Was used a few times for proof of concept but I don’t recall it being used in anger.

KC-30A cabin instrumentation

We installed a whole ground telemetry system into a KC-30A cabin to be able to conduct hornet AAR clearance testing anywhere in the country. Hornet was instrumented with cameras in the cockpit and a strain gauged fuel probe (courtesy of NAVAIR).

Non-intrusive Sensors

We trialled some stick on, wireless sensors (accelerometers) which are still under development with a RAAF contractor. This non-intrusive philosophy aimed to minimise the hard wiring modifications and reduce install/removal time, without loss of data integrity. Plenty of work to be done but the proof of concept worked well: A wireless receiver unit installed to the aircraft/in a pod and sensors remaining installed up to supersonic speeds, controller by an iPad in the cockpit. First trial was on a Yak52 by the contractor, then with the RAAF on a PC-9 and finally on a classic hornet. FYI vibration characteristics weren’t overly affected by the 3M tape which was an interesting result! The recording unit and tablet app were also designed by an industrial design company with actual ease of use/good design principles considered. So a very nice change from the usual hard to use/easily damaged pins we see on existing FTI systems.

Boxkite Instrumentation

One fun one to wrap up – ARDU were asked in 2013-14 to evaluate a RAAF museum Bristol Boxkite for suitability for flying at a centenary of military aviation airshow in 2014. Instrumentation was rudimentary but effective – a GPS/accelerometer near the CG, a series of Go Pros and a stick deflection protractor. That was a really interesting and fun program to be a part of.

Editor’s note: special thanks to Jeremy who has corresponded with me several times over the years.